Choosing the best sump pump depends largely on your situation. It’s not a one size fits all matter and choosing one carelessly can do more harm than good. There are a lot of choices out there and it can get confusing finding the right one. I’ll try to make it easier by sharing with you how to choose a sump pump.

We’ll compare the different types, discuss how to size, and answer a few important questions you might be having. Let’s move on.

Steps on how to choose a sump pump

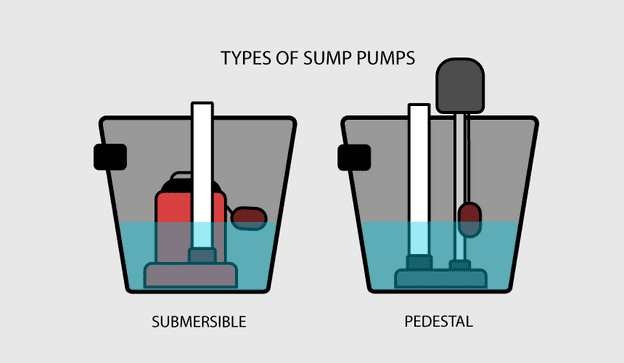

1. Pick a type: submersible vs. pedestal sump pumps

There are two types of sump pumps: pedestal type and submersible type. They’re both great but each has its own strengths and weaknesses.

Pedestal Type

- Lasts longer

- Generally cheaper

- Has longer operating cycles

- The motor is above the sump pit

Submersible Type

- Quieter

- More compact

- Can handle solids better

- Fully submerged underwater

2. Choose the capacity: How much HP do you need?

For most homeowners, a ⅓ HP sump pump is usually enough. It can do the job perfectly if you have light to moderate flooding.

In case of heavy flooding, you can choose a ½ HP sump pump. Just make sure that you have a large enough basin for the pump you choose as having a small basin for a powerful pump may burn the motor from frequent on-and-off.

If you already have a pump installed, you can look at that pump’s capacity and choose the same if it lasted for more than 5 years and can clear the water out in less than 10 minutes. Otherwise, you should choose the next size larger.

On the other hand, if it didn’t last long and only needed less than 15 seconds to clear the water out then you may need a smaller pump.

For those with really small basins, a small sump pump with 1/4 HP may be what you’re looking for although it would be better to have a larger basin if possible.

3. Be conscious of build quality

We want a pump that’s made with the best quality and materials we can afford. For a sump pump, this would mean it can stand against wear and tear and corrosion. The whole assembly must be sealed tight and remain that way for decades to come.

Pump

The base should be made of a corrosion resistant material that can also withstand erosion and buildup.

Cast iron is strong but it’s prone to corrosion that may restrict your intake after some time unlike stainless steel and thermoplastic. Although it still depends on how well the coating is applied, if you have high mineral content in your water, you should consider the alternatives.

Its impeller and the shaft that holds it must also be strong enough to not break or erode easily in case of debris.

Motor

The motor housing must remain strong and rust-free to prevent water from getting in while allowing the heat to go out. This will help the motor maintain a low temperature level at all times.

Since buildup and corrosion isn’t much of a problem for the housing, cast iron is a good choice. It can transfer heat really well unlike thermoplastics.

The motor itself must be reliable and of high quality. It should be UL listed, the same with the power cord, which means it’s been certified for safety and reliability.

Switch

The float is the most sensitive part in a sump pump assembly because it has the most moving parts. Dirt and rust can impede those parts from moving and ultimately cause the pump to misread the water level.

The float switch’s ball should be buoyant and resistant to punctures to keep an accurate reading of the water level at all times. The whole switch assembly must be resistant to rust and dirt accumulation.

4. Look for the best features

You need a pump that you know you can count on every single time. If you want to sleep soundly even during stormy nights, you need to have a pump with the right tricks.

Pump

A non-clogging impeller that allows larger solids to pass through is a must-have for any pump. Clogs can prevent the pump from sucking any water and can even damage the motor. Although these pumps really shouldn’t be handling solids, we want to know they can just in case they need to.

Motor

Ideally, the motor should be rated for continuous use which means it can run non-stop without a problem. But if you have a properly sized pump, one that’s only rated for intermittent use is usually good enough.

It should have thermal overload protection which cuts the power when it gets too hot for some reason and an automatic reset which starts it again when it’s cooled. Since a few degrees above the standard limit can greatly reduce motor life, this is an important feature the pump shouldn’t live without.

If it has properly lubricated bearings that enable a more stable operation and lower noise levels, then that’s even better. These bearings help keep the motor cool by reducing friction between parts.

An oil-filled motor will also have better temperature compared to water-cooled motors. On top of that, it helps act as a lubricant for the pump’s moving parts. The only catch is if you’re pumping out to a pond or somewhere with aquatic life where the oil will contaminate the water in case of leaks.

Switch

The float switch can either be integrated into the pump or piggybacked. The latter is usually where you have two cords leading to your outlet and the plug of the switch has a piggyback port where you can insert the plug of the pump.

There are 3 common types of switch:

- The tethered type switch is preferred if you have a larger basin. As long as it doesn’t get caught, it’s usually very reliable and has a longer range between the on and off points.

- If the pump is for smaller basins, a more space-efficient vertical switch may be perfect. The only problem is that it usually has a shorter range. This can cause the pump to turn on and off much more frequently or what we call short cycle.

- The electronic switch is the most reliable type with both of the advantages of the previous two and the added reliability due to having no moving parts. It’s guaranteed to last longer than either of the two but it’s also a lot more expensive. But if you’re looking to cover every possibility then this will definitely be a big help.

5. Make sure it’s easy to install

Installation is the last consideration for choosing a sump pump. Since a lot of us are installing the pump on our own, a pump that’s easy to install is a big help.

- The pump has to be light so it’s easy to carry into the pit and the dimensions must allow easy handling of the pump

- Small basin requirement by the manufacturer is also great to give us more options on our installation

- A piggyback switch is recommended for easier replacement in case the original goes bad although the integral switch is fine for most cases too.

- The cord length is also considered since extension cords should not be used on sump pumps for safety reasons, check the distance between your pit and the outlet.

- Lastly, the user manual must be detailed and easy to follow. There are questions that only the manufacturer can answer and it should be presented clearly in the provided manual.

Wrapping Up

Choosing a sump pump is really simple and easy. All you need is to know if you want a pedestal sump pump which lasts longer or a submersible sump pump that’s quieter, the capacity you need, and the little things you need to watch out for in the pump, motor, and switch. With what you know now, I hope you’re ready to pick up the best sump pump for your home.